Material Purity and Grain Morphology: The Unspoken Drivers of the Europe Silica Sand for Glass Making Market

Material purity and grain morphology are emerging as key, yet often overlooked, factors driving the Europe silica sand for glass making market's growth.

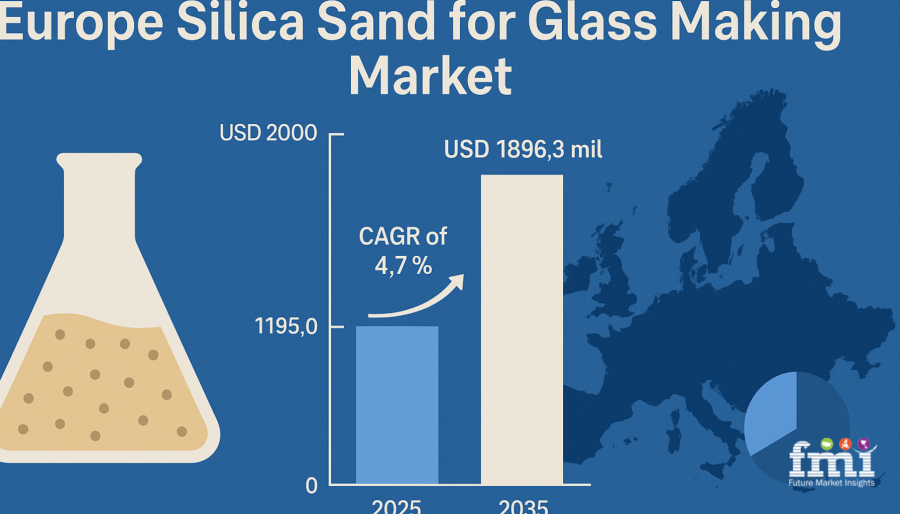

NEWARK, DE, UNITED STATES, May 28, 2025 /EINPresswire.com/ -- The Europe silica sand for glass making market is often analyzed through the lenses of supply chains, demand from the construction and automotive industries, and regional production capacities. While these factors are important, they only scratch the surface of what truly governs the dynamics of this specialized market. A deeper, more technical aspect—namely, the purity levels and grain morphology of silica sand—is rarely discussed but plays a crucial role in shaping the market. This article brings to light the underappreciated yet impactful characteristics of silica sand that determine its suitability for various types of glass manufacturing. Through this lens, we’ll uncover how grain size distribution, chemical composition, and advanced beneficiation technologies are silently influencing Europe’s silica sand market.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-15410

𝐓𝐡𝐞 𝐏𝐮𝐫𝐢𝐭𝐲 𝐈𝐦𝐩𝐞𝐫𝐚𝐭𝐢𝐯𝐞: 𝐖𝐡𝐲 𝟗𝟗.𝟗% 𝐒𝐢𝐎₂ 𝐈𝐬𝐧’𝐭 𝐉𝐮𝐬𝐭 𝐚 𝐍𝐮𝐦𝐛𝐞𝐫

Silica sand used in glass manufacturing must meet extraordinarily high purity standards. While the benchmark for basic container glass may be around 99% silicon dioxide (SiO₂), the demands for flat glass, solar panel glass, and especially optical glass push the requirement even higher—up to 99.9% SiO₂. This level of purity is not a marketing gimmick but a technical necessity. Even trace amounts of impurities like iron oxide can cause unwanted coloration in the final glass product. In Europe, where glass manufacturers serve sectors with strict quality controls—including pharmaceutical packaging and photovoltaic panels—high-purity silica sand has become a critical resource. The concentration of such high-grade deposits is relatively rare, making purity a hidden but powerful lever in determining sand value, supply limitations, and competitive positioning in the European market.

𝐆𝐫𝐚𝐢𝐧 𝐌𝐨𝐫𝐩𝐡𝐨𝐥𝐨𝐠𝐲: 𝐓𝐡𝐞 𝐌𝐢𝐜𝐫𝐨𝐬𝐜𝐨𝐩𝐢𝐜 𝐅𝐞𝐚𝐭𝐮𝐫𝐞 𝐰𝐢𝐭𝐡 𝐌𝐚𝐜𝐫𝐨𝐞𝐜𝐨𝐧𝐨𝐦𝐢𝐜 𝐄𝐟𝐟𝐞𝐜𝐭𝐬

While chemical purity is often highlighted in technical sheets and procurement specifications, the physical characteristics of silica grains are less frequently discussed. Yet grain morphology—specifically the shape and distribution of particles—can dramatically impact glass melting behavior, furnace efficiency, and product consistency. Rounded grains with uniform size tend to melt more predictably, leading to smoother production runs and fewer defects. European suppliers that can deliver consistently spherical grains have a competitive edge in markets such as fiber optics and architectural glass, where quality cannot be compromised. These properties are shaped not only by the geological origin of the sand but also by how it is mined and processed. Therefore, grain morphology is emerging as a subtle but vital differentiator in the European silica sand landscape.

𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐃𝐢𝐬𝐩𝐚𝐫𝐢𝐭𝐢𝐞𝐬 𝐚𝐧𝐝 𝐭𝐡𝐞 𝐂𝐨𝐧𝐜𝐞𝐧𝐭𝐫𝐚𝐭𝐢𝐨𝐧 𝐨𝐟 𝐏𝐫𝐞𝐦𝐢𝐮𝐦 𝐃𝐞𝐩𝐨𝐬𝐢𝐭𝐬

In Europe, silica sand resources are not uniformly distributed. Countries like Belgium, Germany, and France host some of the continent’s most prized deposits, characterized by their high purity and favorable grain shapes. In contrast, other regions may struggle with contamination by iron, clay, or organic materials, which necessitate costly processing.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/europe-silica-sand-market

This disparity affects not only local production economics but also the broader supply chain. For instance, the northern French basin is a critical source for silica sand used in solar glass, and disruptions there—whether due to environmental regulation or labor issues—can send ripples across European industries reliant on specialty glass. The high concentration of premium-grade resources in just a handful of European regions creates a competitive bottleneck that is seldom highlighted in market overviews but is deeply influential.

𝐁𝐞𝐧𝐞𝐟𝐢𝐜𝐢𝐚𝐭𝐢𝐨𝐧 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬: 𝐓𝐡𝐞 𝐆𝐚𝐦𝐞-𝐂𝐡𝐚𝐧𝐠𝐞𝐫 𝐁𝐞𝐡𝐢𝐧𝐝 𝐭𝐡𝐞 𝐒𝐜𝐞𝐧𝐞𝐬

Technological innovation in beneficiation—particularly magnetic separation, acid leaching, and froth flotation—is enabling the extraction of purer silica sand from lower-quality deposits. European processors have invested heavily in such technologies to overcome the natural limitations of regional deposits and meet the increasing quality requirements of the glass industry. Acid leaching, for instance, is particularly effective in removing iron contaminants that cause discoloration in clear glass. Though this process adds to production costs and raises environmental concerns, it allows more suppliers to enter the premium-grade market. This shift is changing the competitive landscape, turning what were once marginal deposits into commercially viable sources, thus altering the supply-demand equation across Europe.

𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥 𝐑𝐞𝐠𝐮𝐥𝐚𝐭𝐢𝐨𝐧𝐬 𝐚𝐧𝐝 𝐓𝐡𝐞𝐢𝐫 𝐈𝐦𝐩𝐚𝐜𝐭 𝐨𝐧 𝐑𝐞𝐬𝐨𝐮𝐫𝐜𝐞 𝐀𝐜𝐜𝐞𝐬𝐬𝐢𝐛𝐢𝐥𝐢𝐭𝐲

Europe’s strict environmental regulations present a double-edged sword for the silica sand market. On one hand, they safeguard ecosystems and ensure responsible mining practices. On the other hand, they limit the accessibility of deposits, especially in protected areas or regions facing strong public opposition to mining. Germany and the Netherlands, for example, have implemented zoning restrictions that constrain silica sand mining operations, even in geologically favorable zones. This regulatory climate pushes manufacturers to either import higher-grade sand or invest in more intensive beneficiation techniques—both of which inflate production costs. The interplay between environmental policy and geological access is a less visible but potent driver of the European silica sand for glass making market.

𝐓𝐡𝐞 𝐑𝐨𝐥𝐞 𝐨𝐟 𝐂𝐢𝐫𝐜𝐮𝐥𝐚𝐫 𝐆𝐥𝐚𝐬𝐬 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐢𝐧 𝐑𝐞𝐝𝐮𝐜𝐢𝐧𝐠 𝐒𝐚𝐧𝐝 𝐃𝐞𝐦𝐚𝐧𝐝

An emerging trend with significant implications for the silica sand market is the push toward circular glass production. European glass manufacturers are increasingly integrating cullet (recycled glass) into their production lines to reduce energy usage and raw material demand. This shift has the potential to alleviate some pressure on high-purity silica sand supply, particularly in the container and flat glass segments. However, certain types of specialty glass—such as borosilicate or optical glass—still require virgin silica due to precise chemical specifications. While circularity might modestly decelerate growth in raw sand demand, it will not eliminate the need for ultra-pure deposits. Thus, the market is expected to bifurcate, with recycled glass supplementing commodity-grade production while ultra-pure silica sand continues to fuel high-value applications.

𝐆𝐞𝐧𝐞𝐫𝐚𝐥 & 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/general-and-advanced-materials

𝐀 𝐅𝐨𝐫𝐞𝐜𝐚𝐬𝐭 𝐑𝐨𝐨𝐭𝐞𝐝 𝐢𝐧 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧, 𝐍𝐨𝐭 𝐕𝐨𝐥𝐮𝐦𝐞 𝐀𝐥𝐨𝐧𝐞

Market forecasts for silica sand in Europe often focus on volume growth, driven by construction and solar energy expansion. However, the future of this market will be equally influenced by precision—how narrowly defined technical specifications are met, how consistently quality is maintained, and how agile producers can be in tailoring their sand to application-specific needs. For example, the rising demand for ultra-clear solar glass panels in Germany and Spain cannot be met by average-quality silica. Only producers that can supply sand with less than 100 ppm of iron content and a tightly controlled grain size distribution will remain competitive. Therefore, technical precision—not just volume—will define success in the Europe silica sand for glass making market.

𝐄𝐮𝐫𝐨𝐩𝐞 𝐒𝐢𝐥𝐢𝐜𝐚 𝐒𝐚𝐧𝐝 𝐟𝐨𝐫 𝐆𝐥𝐚𝐬𝐬 𝐌𝐚𝐤𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Purity:

- High

- Ultra High

By Application:

- Flat Glass

- Fiber Glass

- Glass Container

- Colored

- Colorless

- Special & Technical

- Tableware Glass

- Others

By End Use:

- Food & Beverage Packaging

- Industrial

- Pharmaceutical

- Scientific Instrument & Analytical Research

- Construction

- Automotive

- Cookware & Utensils

By Region:

- Germany

- Italy

- France

- United Kingdom

- Spain

- BENELUX

- NORDIC

- Russia

- Rest of Europe

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Alpha Olefin Sulfonates Market: https://www.futuremarketinsights.com/reports/alpha-olefin-sulfonates-market

Acetamide MEA Market: https://www.futuremarketinsights.com/reports/acetamide-mea-market

Cutting Fluid Market: https://www.futuremarketinsights.com/reports/cutting-fluid-market

Lauryl Dimethyl Amine Oxide Market: https://www.futuremarketinsights.com/reports/lauryl-dimethyl-amine-oxide-market

APAC Fluoroelastomer Market: https://www.futuremarketinsights.com/reports/apac-fluoroelastomer-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release